Top 10 Best Cobot Welding this 2025

Automation continues to reshape the manufacturing industry, and cobot welding is at the forefront of this transformation. By combining the precision of robotics with the adaptability of human operators, cobot welding delivers consistent weld quality, boosts productivity, and enhances workplace safety. In 2025, this guide presents the top 10 cobot welding systems, helping manufacturers choose the best solution that matches their production needs and budget.

What Is Cobot Welding?

Cobot welding is the use of collaborative robots (cobots) to perform welding tasks in manufacturing. These robots are designed to work safely alongside humans and are equipped with welding tools such as MIG, TIG, or laser torches. Cobot welding delivers precise, consistent welds that enhance productivity, quality, and safety, while providing flexibility to handle various tasks and production demands.

Criteria for Selecting the Best Cobot Welders

When choosing a cobot for welding, consider:

- User-Friendly Interface: Easy programming with touchscreens or teach pendants.

- Flexibility and Compatibility: The cobot can perform various welding methods and handle different workpiece sizes, while easily fitting into existing equipment and production lines.

- Easy Installation and Maintenance: Simple setup, modular design, and local support for quick repairs.

- Precision and Stability: Accurate, consistent welds with features like real-time monitoring and fixtures.

- Advanced Vision and AI: Built-in vision and AI for seam tracking, defect detection, and adaptive welding.

These factors help manufacturers improve productivity, safety, and weld quality.

See also: effective bookkeeping techniques guide

Top 10 Best Cobot Welding Systems in 2025

Based on recent industry insights, here are the top 10 collaborative robot (cobot) welding systems in 2025, along with their key features and applications:

Top 1: Techman Robot (TM Series)

Built-in AI vision for seam tracking, touchscreen programming, compact design, and payloads from 5–20 kg.

- Pros: Affordable, easy to set up, safe to work alongside humans.

- Cons: Some models are lightweight and compact, making them easy to handle and ideal for tight spaces.

Best For: Small to medium manufacturers and precision tasks in tight spaces.

Top 2: Universal Robots (UR Series)

Modular design, safe for human collaboration, and user-friendly programming software.

- Pros: Very flexible, extensive global support, quick deployment.

- Cons: Higher initial cost and may need extra tools.

Best For: Medium to large operations that need flexibility and quick task changes.

Top 3: FANUC CRX Series

High payload, easy programming, compact, and robust design.

- Pros: Works well for small, varied jobs, reliable, and low maintenance.

- Cons: More expensive, less flexible than modular systems.

Best For: Jobs that require strong robots for heavy or repetitive work.

Top 4: ABB GoFa Cobots

Accurate welding with precise torch control, safe for humans without safety cages, and easy programming via the Easy Teach Device.

- Pros: High precision for complex joints, integrates smoothly into workflows, and enhances safety for collaborative environments.

- Cons: Higher initial cost, may need extra accessories for specific tasks.

Best For: Small to medium manufacturers who need accurate and flexible robots in small spaces.

Top 5: Yaskawa Motoman HC Series

Flexible payload options (HC10, HC20), easy welding control with Universal Weldcom Interface, and safe collaborative design.

- Pros: Highly adaptable, strong global support, quick deployment.

- Cons: Higher upfront investment, may require extra accessories.

Best For: Medium to large manufacturers who need flexible robots that can switch tasks quickly.

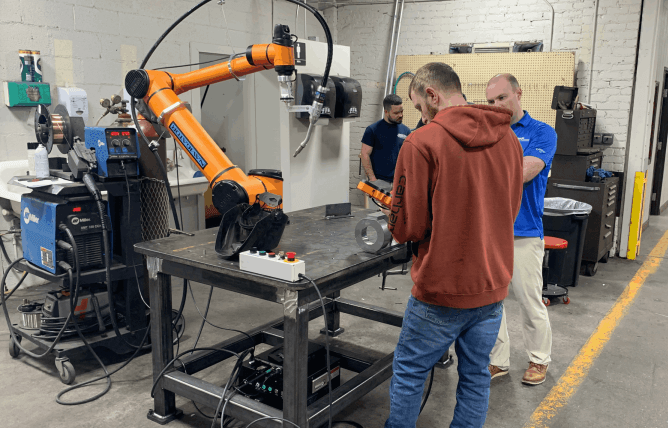

Top 6: KUKA Collaborative Robots

Millimeter-level precision, supports MIG, TIG, and plasma welding, and slim design for confined spaces.

- Pros: Good for high-mix, low-volume production, reliable, and low maintenance.

- Cons: Can be more expensive and less flexible than modular systems.

Best For: Low-volume production requiring high precision and versatile welding.

Top 7: Doosan Robotics H Series

High payload (up to 25 kg), extended reach, advanced safety features.

- Pros: Great for heavy work, quick payback, and works efficiently without changing the workspace.

- Cons: Overpowered for light tasks, a larger footprint requires more space.

Best For: Large-scale assembly, palletizing, and heavy-duty welding tasks.

Top 8: Standard Bots RO1

Supports MIG, TIG, and plasma welding, very precise, AI-enabled, with vision and collision detection for safe teamwork.

- Pros: Affordable, easy no-code programming, compact for small spaces.

- Cons: Limited payload, not suitable for high-speed, high-volume production.

Best For: Small to medium manufacturers who need careful and flexible robots for detailed welds in small areas.

Top 9: Omron TM Series

Built-in camera for pattern recognition, a user-friendly programming interface, and safe for human collaboration without cages.

- Pros: Compact, versatile for tasks beyond welding (assembly, inspection), quick integration into production lines.

- Cons: Limited payload and reach may not suit heavy-duty or extended tasks.

Best For: Light-duty assembly, inspection, or material handling in space-constrained environments.

Top 10: Dobot CR Series

Handles heavy loads up to 20 kg, reaches up to 1700 mm, and has advanced safety features for working with people.

- Pros: High precision, flexible for multiple applications (welding, packaging, palletizing), easy to program.

- Cons: Higher initial cost, larger footprint requires more workspace.

Best For: Heavy-duty tasks, large-scale assembly, and applications needing high payload and extended reach.

Benefits of Using Cobot Welders in 2025

In 2025, cobots are transforming welding by boosting productivity, quality, and safety in factories.

- Higher Productivity: They work non-stop, helping factories finish jobs faster.

- Better Quality: Cobots utilize AI and sensors to produce accurate welds, resulting in fewer mistakes and less rework, which in turn creates stronger and more reliable products.

- Safer Workplaces: Cobots handle dangerous tasks and use safety features to protect workers.

- Lower Costs – By reducing waste, saving materials, and cutting labor expenses, cobot welding quickly pays for itself and becomes cost-effective.

- Flexible and Easy to Use – Cobots can be reprogrammed for different welding jobs and moved to various stations, making them adaptable to changing needs.

- Helps with Labor Shortages – Cobots take over routine welding tasks, allowing skilled welders to focus on complex and high-value work. This helps factories overcome labor shortages while maintaining productivity and efficiency.

- Smart Factory Integration – Smart Factory Integration allows cobots to use 5G and real-time monitoring to connect with machines, making production lines faster, smarter, and more efficient.

Challenges and Considerations

Using cobot welding systems offers many benefits, but manufacturers should be aware of some challenges:

- Technical Integration: Adding cobots to existing machines and workflows can be complex, sometimes requiring system upgrades or temporary adjustments.

- Worker Training: Although cobots are user-friendly, employees still need training to operate, program, and maintain them effectively.

- Cost and ROI: Cobots involve a significant upfront investment. Smaller companies may find this challenging, but long-term savings and improved efficiency can make it worthwhile.

- Safety: Cobots are designed to work safely alongside humans, but risks remain if used incorrectly. Regular safety checks and adherence to industry standards are essential.

- Maintenance and Support: Cobots require routine inspections, software updates, and repairs. Lack of technical support can be a hurdle for some companies.

- Adapting to Different Tasks: Cobots excel at repetitive tasks, but handling different materials or welding types may need extra programming and expertise.

Cobot welding systems are highly valuable, but maximizing their benefits requires careful planning, proper training, consistent maintenance, strict safety measures, and robust cybersecurity.